Looking Back on a Century of Innovation

How do you summarize 100 years of innovation? Let’s take it decade by decade. Join us on a quick trip down memory lane: 10 customer challenges and 10 innovative solutions across our 10 decades of operation.

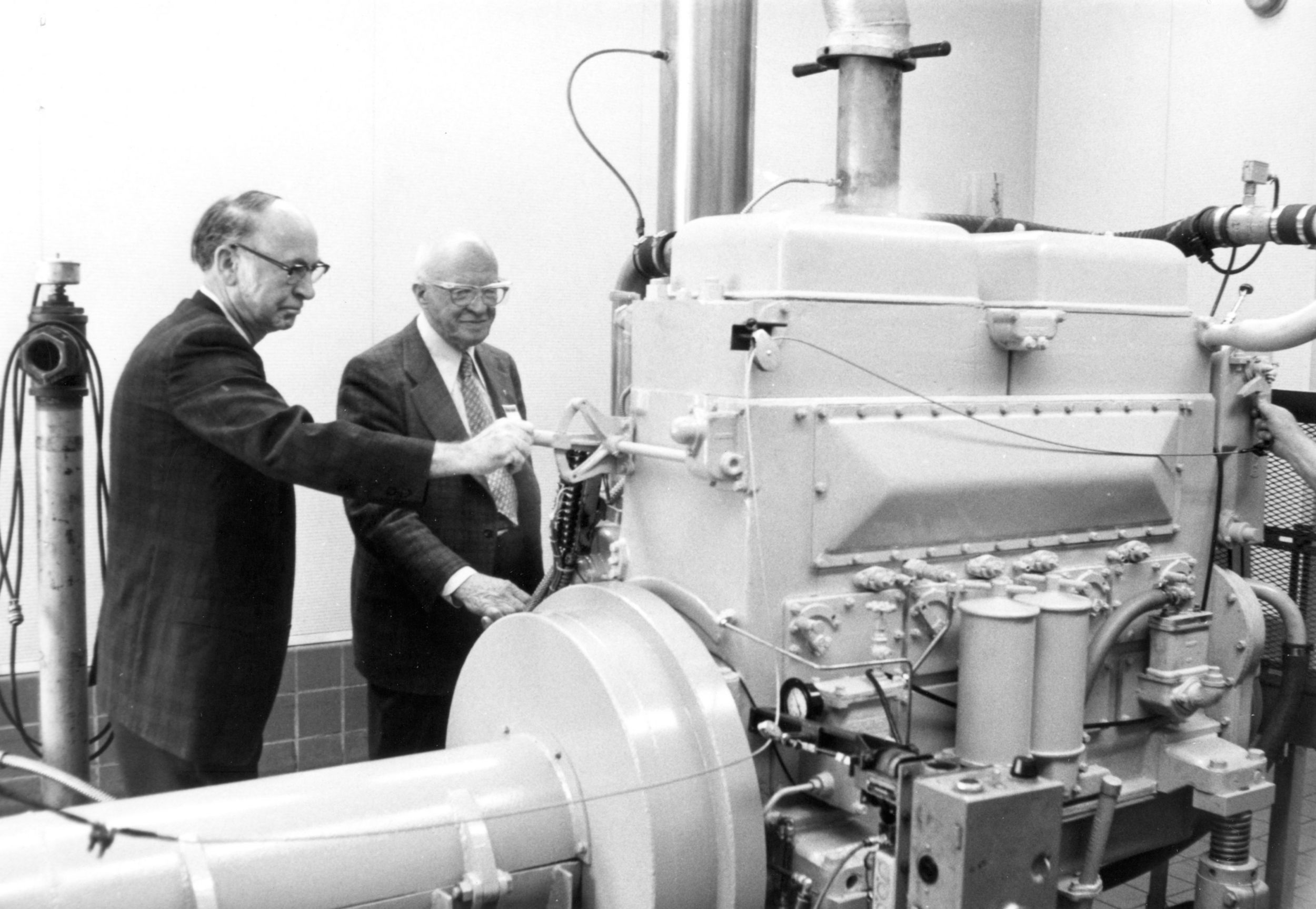

1930s: Old Betsy Brings Diesel to the Masses

The original diesel engines were big, heavy and limited in application—not suited for large-scale projects. So, Caterpillar co-founder C.L. Best and a team of engineers set to work on an entirely new design. The result? Introduced in 1931 and used to power equipment on massive projects, the D9900 helped revolutionize diesel technology and machine performance going forward.

1940s: Hydraulic Controls Give Operators a Lift

Ever watched a barber raise or lower a chair? Then you've seen hydraulics at work. Now imagine lifting not a person but a machine component that weighs hundreds or thousands of pounds. Early equipment operators had to do this task manually—until Caterpillar introduced hydraulic controls in 1948. This breakthrough helped make the work faster, easier and safer for generations to come.

1950s: A Loader and a Tractor Join Forces

Introduced in 1952, our No. 6 Traxcavator Shovel filled a market gap. Previously, customers who wanted to dig and load had to buy a tractor plus a separate shovel attachment. The No. 6 combined them into a single piece of equipment. (Known as a track loader today.) This industry-first design not only offered impressive power and capacity at the time—it also established a blueprint for our future fully integrated designs.

1960s: Metalworking Goes Modern

Slag removal is how steel gets a clean, smooth surface—but it’s a sweaty task at best and a risky one at worst. That’s why a major steel producer asked if we could figure out a way to help operators do the job while staying out of harm’s way. The answer was yes, and in 1969, we delivered two track loaders capable of removing slag via radio remote control. These high-tech machines helped set the stage for our modern remote control and autonomous technology.

1970s: Elevated Sprocket, Elevated Performance

Asked to improve comfort, longevity and traction on our signature piece of equipment, the track-type tractor, Caterpillar engineers had an idea: They separated the drive sprockets from the track roller frame and raised them above the track, then tested the design using parts borrowed from a riding lawnmower. The result exceeded expectations. In 1977, we introduced the elevated sprocket on our D10 dozer, a change that forever altered industry and customer expectations.

1980s: Engines Go Electronic

This decade’s combination of rising gas prices, new air and emissions regulations and booming electronics and computing power led to one of our biggest engine advancements yet. First introduced in 1988 on our 3176 diesel engine, electronic fuel injection replaced the carburetor with a computer-controlled system that optimized fuel and air intake. That improved fuel economy, performance and emissions—and set our customers on the path to meet ever-stricter environmental standards.

1990s: Autonomous Mining Takes Off

Navigating massive equipment around potential obstacles in some of the harshest environments on (and under) Earth is no easy task. Autonomy can help transform the work, removing the operator from the cab to make mining safer and more efficient. In 1996, we unveiled the industry’s first autonomous mining truck. Today, our fleet of autonomous haul trucks is the world’s largest, and we’re introducing autonomy and its benefits into other industries.

2000s: Electric Drive Sets New Efficiency Standards

More than a century after Benjamin Holt built the first track-type tractor, we challenged our engineers to reimagine what these machines could do. Their answer? A dozer powered by a first-of-its-kind electric powertrain. Efficiency was at the heart of our new D7E dozer design. Introduced in 2009, it used less fuel, less fluid and fewer moving parts than the models that came before. For our customers, that translated into reduced upkeep and costs with no sacrifices to performance.

2010s: The Pathway to Reduced Emissions

When the U.S. Environmental Protection Agency finalized its Tier 4 emissions standards for diesel engines, we saw the challenge of reducing particulate matter and nitrogen oxides as an opportunity. Our design teams stepped up, overhauling many of our products in response. In 2014, we delivered our Tier 4 Final solution, creating a pathway to reduce emissions by around 90%. This marked a major step forward in our sustainability journey.

2020s: Electrifying Mining

As electrification transforms industries, we've helped lead the way with multiple innovations for miners. In 2022, we demonstrated our first battery-electric large mining truck and launched a battery-electric underground loader, followed a year later by a semi-autonomous battery-electric prototype underground mining truck. These innovations, developed in collaboration with key customers, are part of our commitment to mining better, together.

Looking Ahead

From the beginning, we’ve worked alongside our customers to rethink the status quo, solve tough problems and shape the future for the better. What challenges will the next 100 years bring? That’s anyone’s guess—but one thing is certain: You can count on Caterpillar to keep pushing the boundaries of innovation in the decades to come to help our customers build a better, more sustainable world.