Excavators: A Journey to Building Better

May 20, 2024

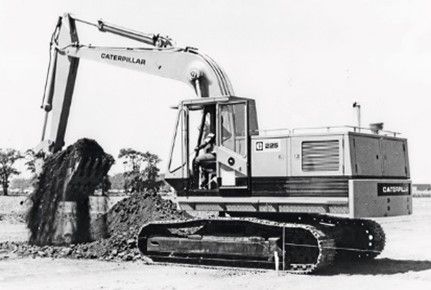

Caterpillar has witnessed a significant evolution in its excavators over the years. In the late 1960s the mining industry in Europe demanded larger and more powerful machines. Responding to this need, the first excavators emerged. In 1970, Caterpillar introduced a prototype excavator in both Europe and the United States. By 1972 Caterpillar introduced its first customer-ready hydraulic excavator, the 225. This revolutionized what was possible at job sites by lifting, digging and loading more effectively.

Over the next 40 years, each iteration of the original excavator would bring improvements in design that resulted in reduced fuel consumption, lowered maintenance costs and increased performance.

In 2007, Caterpillar introduced the 320D excavator model. This model incorporated technology to optimize engine performance and provide low exhaust emissions to meet global emission regulations. The development of the 320D helped pave the way for future models

The Next Generation

The Next Generation 320 hydraulic excavator became available to customers in 2017 as a powerful and fuel-efficient machine for medium- to heavy-duty applications, all with a focus on helping to meet customers’ climate- and business-related goals:

- The Next Generation family of hydraulic excavators optimizes machine system performance to provide notable improvements in productivity and efficiency. The success of the system spurred additional models to be moved to this platform each subsequent year following the launch through 2022, now implemented on the entire excavation product line of more than 50 models.

- A combination of lower engine speed and a large hydraulic pump delivers top performance while burning less fuel.

- The 320 Cat® diesel engine can operate on up to 20% biodiesel fatty acid methyl ester (FAME) or 100% renewable diesel, hydrogenated vegetable oil (HVO) and gas-to-liquid (GLT) fuels.*

- VisionLink®** displays the CO2 emissions for monitored assets, calculated by fuel type for the runtime fuel burned each day in a selected date range.

- Cat® Grade technologies combine advanced guidance with optional automated machine control, helping you reach grading targets while reducing fuel burn and greenhouse gas emissions by improving efficiency, job site productivity, and accuracy.

- Auto Engine Speed Control reduces unnecessary fuel burn and greenhouse gas emissions by allowing the engine to automatically go into idle mode when the machine is not working.

- Cat® Payload for excavators provides on-the-go material weighing which helps reduce fuel burn by improving loading efficiency, job site productivity, and eliminating trips to the scale.

- Extended maintenance intervals not only reduce downtime but decrease the amount of fluid and filters that are replaced over the life of the machine.

These technologies and improvements result in up to 30% reduction of CO2 emissions from the 320D.

What’s Next

Caterpillar has a nearly 100-year history of innovation. The journey of Caterpillar’s excavators is a shining example of this innovative evolution—from shaping the industry around the world during the 1970s and 80s to providing customers with a diverse portfolio of products, services and solutions that lower greenhouse gas (GHG) emissions, improve efficiency and productivity, and deliver energy flexibility.

Today, Caterpillar is working to support our customers through the energy transition by designing solutions that help build a better, more sustainable world. The next evolution of the 320 excavator includes the 320 medium excavator battery electric prototype.

The addition of the battery electric prototype continues our commitment to provide a variety of solutions to meet customers on their sustainability journey today and support them into the future as we power the next generation of machines.

*Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (for use of blends higher than 20% biodiesel, consult a Cat dealer). Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same emissions from traditional fuels.

** Estimated CO2 emissions reduction based on estimated fuel burn rate recorded in Product Link data of machines working in a mix of applications in Europe January through December 2019. Fuel burn rate measured as Liter per Hour. Fuel burn rate improvements resulting from multiple new machine technologies, including new electro-hydraulic system, more efficient on-demand fans, lower engine RPM and new power modes.

-

Cat® Certified Rebuilds: A Win-Win-Win for Sustainability

Cat® Certified Rebuilds help customers save money while avoiding GHG emissions.

Learn More Sustainability -

2024 Sustainability Report

Our 2024 sustainability report demonstrates Caterpillar’s progress to help our customers’ build a more sustainable world.

View Report